【美标对夹式止回阀概述】

H71H(W)美标对夹式止回阀由阀体、阀瓣、弹簧等组成,水平或垂直安装于管路系统,防止介质倒流,具有结构短、体积小、重量轻;

阀瓣关闭快速,水锤压力小;流道通畅,流体阻力小;动作灵敏,密封性能好。

【美标对夹式止回阀结构图】

【美标对夹式止回阀的型号、材料及主要参数】

|

配管法兰 |

公称压力 |

常规产品型号 |

JB/T 74

~90、

GB/T 9112

~9124、

HG 20592

~20614 |

PN1.0MPa |

H71H-10C |

H71W-10P |

H71W-10P8 |

H71W-10P3 |

H71W-10R |

H71W-10R8 |

H71W-10R3 |

|

PN1.6MPa |

H71W-16C |

H71W-16P |

H71W-16P8 |

H71W-16P3 |

H71W-16R |

H71W-16R8 |

H71W-16R3 |

|

PN2.5MPa |

H71W-25 |

H71W-25P |

H71W-25P8 |

H71W-25P3 |

H71W-25R |

H71W-25R8 |

H71W-25R3 |

|

PN4.0MPa |

H71W-40 |

H71W-40P |

H71W-40P8 |

H71W-40P3 |

H71W-40R |

H71W-40R8 |

H71W-40R3 |

|

PN6.3MPa |

H71W-63 |

H71W-63P |

H71W-63P8 |

H71W-63P3 |

H71W-63R |

H71W-63R8 |

H71W-63R3 |

|

PN10.0MPa |

H71W-100 |

H71W-100P |

H71W-100P8 |

H71W-100P3 |

H71W-100R |

H71W-100R8 |

H71W-100R3 |

|

PN16.0MPa |

H71W-160 |

H71W-160P |

H71W-160P8 |

H71W-160P3 |

H71W-160R |

H71W-160R8 |

H71W-160R3 |

GB/T 9112

~9124、

HG 20615

~20635、

SH 3406 |

PN2.0MPa |

H71H-20C |

— |

H71W-20P8 |

H71W-20P3 |

— |

H71W-20R8 |

H71W-20R3 |

|

PN5.0MPa |

H71H-50 |

— |

H71W-50P8 |

H71W-50P3 |

— |

H71W-50R8 |

H71W-50R3 |

|

PN11.0MPa |

H71H-110 |

— |

H71W-110P8 |

H71W-110P3 |

— |

H71W-110R8 |

H71W-110R3 |

|

PN15.0MPa |

H71H-150 |

— |

H71W-150P8 |

H71W-150P3 |

— |

H71W-150R8 |

H71W-150R3 |

|

ANSI B 16.5 |

Class150 |

H71H-A1C |

— |

H71W-A1P8 |

H71W-A1P3 |

— |

H71W-A1R8 |

H71W-A1R3 |

|

Class300 |

H71H-A3 |

— |

H71W-A3P8 |

H71W-A3P3 |

— |

H71W-A3R8 |

H71W-A3R3 |

|

Class600 |

H71H-A6 |

— |

H71W-A6P8 |

H71W-A6P3 |

— |

H71W-A6R8 |

H71W-A6R3 |

|

Class900 |

H71H-A9 |

— |

H71W-A9P8 |

H71W-A9P3 |

— |

H71W-A9R8 |

H71W-A9R3 |

|

|

阀体 |

WCB(A105) |

ZG1Cr18Ni9Ti |

CF8(304) |

CF3(304L) |

ZG1Cr18Ni12Mo2Ti |

CF8M(316) |

CF3M(316L) |

|

阀瓣 |

2Cr13 |

1Cr18Ni9Ti |

0Cr18Ni9 |

00Cr19Ni10 |

1Cr18Ni12Mo2Ti |

0Cr17Ni12Mo2 |

00Cr17Ni14Mo2 |

|

压圈 |

2Cr13 |

1Cr18Ni9Ti |

0Cr18Ni9 |

00Cr19Ni10 |

1Cr18Ni12Mo2Ti |

0Cr17Ni12Mo2 |

00Cr17Ni14Mo2 |

|

弹簧 |

0Cr18Ni9 |

0Cr18Ni9 |

0Cr18Ni9 |

00Cr19Ni10 |

0Cr17Ni12Mo2 |

0Cr17Ni12Mo2 |

00Cr17Ni14Mo2 |

|

|

适用介质 |

水、蒸汽、油品等 |

硝酸等腐蚀性介质 |

强氧化性介质 |

醋酸等腐蚀性介质 |

尿素等腐蚀性介质 |

|

适用温度(℃) |

-29~425 |

-196~540 |

-196~425 |

-196~540 |

-196~455 |

|

注:本表为常规对夹式止回阀的型号编制、主要零件材料及适用工况,其他要求及其型号编制参见对夹止回阀型号编制方法。 |

【美标对夹式止回阀主要连接尺寸】

|

压力级 |

口径 |

尺寸(mm) |

|

配管法兰(供参考) |

|

NPS |

DN |

L |

D |

D2 |

D3 |

D4 |

|

|

螺栓直径d |

|

|

in |

mm |

|

|

1/2 |

15 |

16 |

46 |

15 |

25 |

25 |

0.28 |

60.5 |

4 |

1/2 |

M14 |

75 |

|

3/4 |

20 |

19 |

56 |

19 |

30 |

30 |

0.42 |

70 |

4 |

1/2 |

M14 |

90 |

|

1 |

25 |

22 |

65 |

24 |

36 |

36 |

0.56 |

79.5 |

4 |

1/2 |

M14 |

90 |

|

11/4 |

32 |

28 |

74 |

31 |

43 |

43 |

0.75 |

89 |

4 |

1/2 |

M14 |

100 |

|

11/2 |

40 |

31.5 |

84 |

39 |

52 |

52 |

1.3 |

98.5 |

4 |

1/2 |

M14 |

105 |

|

2 |

50 |

40 |

103 |

48 |

62 |

62 |

2.1 |

120.5 |

4 |

5/8 |

M16 |

125 |

|

21/2 |

65 |

46 |

122 |

62 |

75 |

75 |

2.8 |

139.5 |

4 |

5/8 |

M16 |

130 |

|

3 |

80 |

50 |

135 |

76 |

90 |

90 |

3.6 |

152.5 |

4 |

5/8 |

M16 |

135 |

|

4 |

100 |

60 |

173 |

95 |

112 |

112 |

4.8 |

190.5 |

8 |

5/8 |

M16 |

150 |

|

5 |

125 |

90 |

195 |

110 |

125 |

132 |

12 |

216.0 |

8 |

3/4 |

M20 |

180 |

|

6 |

150 |

106 |

220 |

127 |

150 |

158 |

17 |

241.5 |

8 |

3/4 |

M20 |

210 |

|

8 |

200 |

140 |

277 |

165 |

200 |

208 |

29 |

298.5 |

8 |

3/4 |

M20 |

240 |

|

压力级 |

口径 |

尺寸(mm) |

|

配管法兰(供参考) |

|

NPS |

DN |

L |

D |

D2 |

D3 |

D4 |

|

|

螺栓直径d |

|

|

in |

mm |

RF |

RJ |

|

|

1/2 |

15 |

25 |

46 |

15 |

25 |

25 |

0.28 |

60.5 |

4 |

1/2 |

M14 |

90 |

— |

|

3/4 |

20 |

31.5 |

56 |

19 |

30 |

30 |

0.42 |

70 |

4 |

1/2 |

M14 |

100 |

— |

|

1 |

25 |

35.5 |

65 |

24 |

36 |

36 |

0.56 |

79.5 |

4 |

1/2 |

M14 |

105 |

120 |

|

11/4 |

32 |

40 |

74 |

31 |

43 |

43 |

0.75 |

89 |

4 |

1/2 |

M14 |

115 |

130 |

|

11/2 |

40 |

45 |

84 |

39 |

52 |

52 |

1.3 |

98.5 |

4 |

1/2 |

M14 |

120 |

135 |

|

2 |

50 |

56 |

103 |

48 |

62 |

62 |

2.1 |

120.5 |

4 |

5/8 |

M16 |

140 |

155 |

|

21/2 |

65 |

63 |

122 |

62 |

75 |

75 |

2.8 |

139.5 |

4 |

5/8 |

M16 |

155 |

170 |

|

3 |

80 |

71 |

135 |

76 |

90 |

90 |

3.6 |

152.5 |

4 |

5/8 |

M16 |

165 |

180 |

|

4 |

100 |

80 |

173 |

95 |

112 |

112 |

4.8 |

190.5 |

8 |

5/8 |

M16 |

175 |

190 |

|

5 |

125 |

110 |

195 |

110 |

125 |

132 |

12 |

216.0 |

8 |

3/4 |

M20 |

210 |

225 |

|

6 |

150 |

125 |

220 |

127 |

150 |

158 |

17 |

241.5 |

8 |

3/4 |

M20 |

230 |

245 |

|

8 |

200 |

160 |

277 |

165 |

200 |

208 |

29 |

298.5 |

8 |

3/4 |

M20 |

270 |

285 |

|

|

1/2 |

15 |

25 |

52 |

15 |

25 |

25 |

0.3 |

66.5 |

4 |

1/2 |

M14 |

95 |

105 |

|

3/4 |

20 |

31.5 |

65 |

19 |

30 |

30 |

0.46 |

82.5 |

4 |

5/8 |

M16 |

110 |

125 |

|

1 |

25 |

35.5 |

72 |

24 |

36 |

36 |

0.6 |

89 |

4 |

5/8 |

M16 |

115 |

130 |

|

11/4 |

32 |

40 |

81 |

31 |

43 |

43 |

0.8 |

98.5 |

4 |

5/8 |

M16 |

125 |

140 |

|

11/2 |

40 |

45 |

94 |

39 |

52 |

52 |

1.5 |

114.5 |

4 |

3/4 |

M20 |

140 |

155 |

|

2 |

50 |

56 |

110 |

48 |

62 |

62 |

2.4 |

127.0 |

8 |

5/8 |

M16 |

145 |

170 |

【美标对夹式止回阀流体阻力系数、流量系数及开启压力】

水的当量体积流量Vw与实际流体的体积流量V按下式换算:

式中:Vw-水的当量体积流量,1/S;

ρ-流体密度,kg/m3;

V-实际流体的体积流量,1/S。

|

|

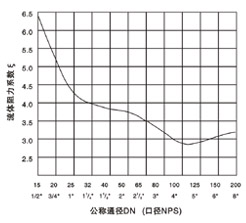

流体力学性能·H71美标对夹式止回阀的流体阻力系数

|

公称通径 |

阀门全开启

时的流体阻

力系数ξ |

常温下阀门全开启时的水流量系数

|

流体的流向

|

|

DN |

NPS |

Kv(m3/h) |

Cv(U.S) |

Cv(U.K)

|

↑ |

↓ |

→ |

|

开启压力近似值KPa |

|

15 |

1/2 |

6.4 |

2.6 |

3.0 |

2.5 |

3 |

2 |

25 |

|

20 |

3/4 |

5.1 |

6.4 |

7.5 |

6.3 |

3 |

2 |

2.5 |

|

25 |

1 |

4.1 |

12.6 |

14.8 |

12.3 |

3 |

2 |

2.5 |

|

32 |

11/4 |

4.1 |

19.7 |

23.1 |

19.3 |

3 |

2 |

2.5 |

|

40 |

11/2 |

3.8 |

29.5 |

34.5 |

28.9 |

3 |

2 |

2.5 |

|

50 |

2 |

3.5 |

54.6 |

63.9 |

53.5 |

3 |

2 |

2.5 |

|

65 |

21/2 |

3.5 |

85.4 |

99.9 |

83.7 |

3 |

2 |

2.5 |

|

80 |

3 |

3.2 |

128 |

150 |

125 |

3 |

2 |

2.5 |

|

100 |

4 |

2.8 |

244 |

286 |

249 |

3 |

2 |

2.5 |

|

125 |

5 |

2.9 |

375 |

439 |

368 |

3 |

1 |

2.2 |

|

150 |

6 |

3.1 |

522 |

611 |

512 |

3 |

1 |

2.2 |

|

200 |

8 |

3.2 |

915 |

1070 |

897 |

3 |

1 |

2.2 |

【美标对夹式止回阀结构特点】

1、结构长度短,其结构长度只有传统法兰止回阀的1/4~1/8

2、体积小、重量轻、其重量只有传统法兰止回阀的1/4~1/20

3、阀瓣关闭快速,水锤压力小

4、水平管道使用,安装方便

5、流道通畅、流体阻力小

6、动作灵敏、密封性能好

7、阀瓣行程短、关阀冲击力小

8、整体结构、简单紧凑、造型美观

9、使用寿命长、可靠性高

|

订货须知:

一、①美标对夹式止回阀产品名称与型号②美标对夹式止回阀口径③美标对夹式止回阀是否带附件以便我们的为您正确选型。

二、若已经由设计单位选定正钢阀门美标对夹式止回阀型号,请按美标对夹式止回阀型号直接向我司销售部订购。

三、当使用的场合非常重要或环境比较复杂时,请您尽量提供设计图纸和详细参数,由我们的正钢阀门专家为您审核把关。